In order for manufacturing companies to adhere to the principles of lean manufacturing, mistakes and defects must be properly defined, addressed, and ultimately prevented in an effective and efficient manner. Mejorando continuamente la calidad de los recambios y comprobándolos antes de su envío gara.

Poka Yoke Konsep Manajemen Produksi Yang Mampu Mencegah Kesalahan – Accurate Online

Alarm signal in the car if the car is driving and the seatbelt is not pluged in to remind the driver of wearing the seat belt.

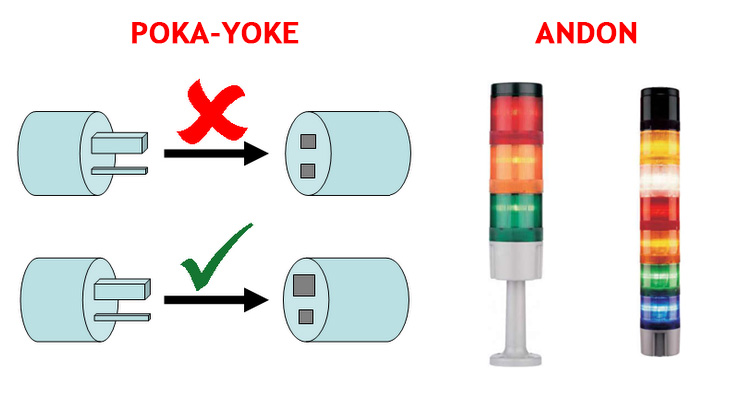

Artigo sobre poka yoke toyota. Mistake is avoided from happening. Poka yoke has different applications, from productive, service, administrative process to the improvement in the usability of a product by the user. Poka yoke is basically classified into two types.

•poka yoke “mistake proofing” •smed (single minute exchanges of dies) although he did not create the concepts of sequence and source inspection, shingo developed a structure of knowing which to use when. In the prevention type of poka yoke the mistake is controlled or avoided before happening at the work place. In the detection type of poka yoke the defective part or process is identified for.

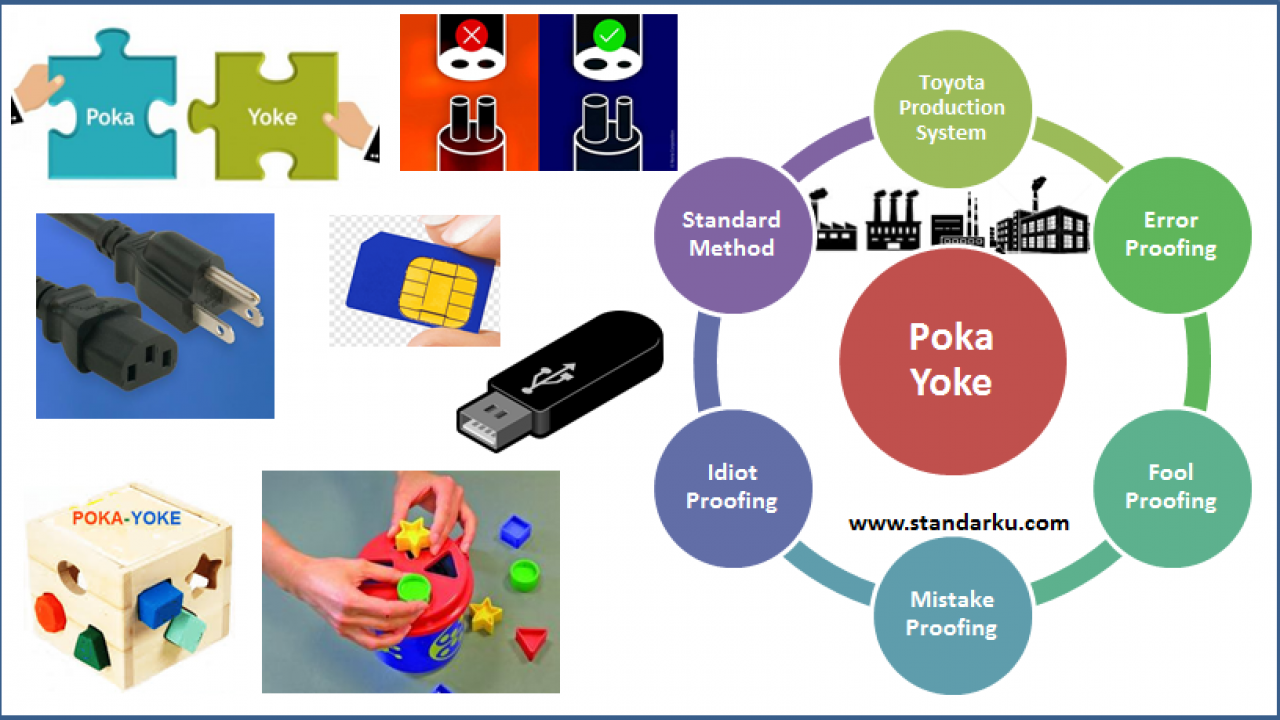

Since then poka yoke has been an inevitable part of manufacturing system. Poka yoke examples in nature. Poka yoke is a frequently used method in lean manufacturing and six sigma to ensure as little errors in a production process as possible.

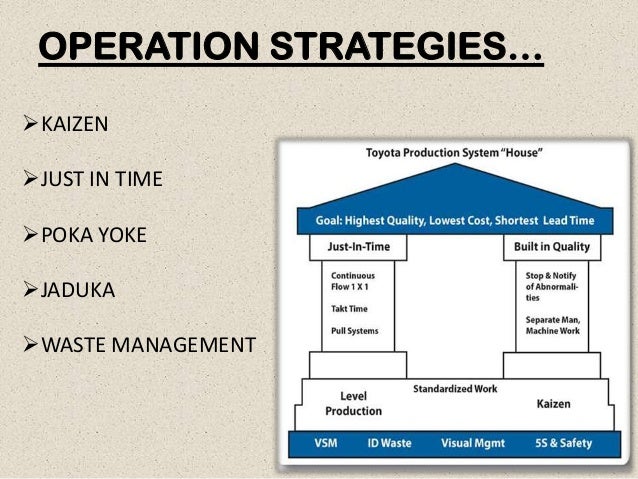

It was originally coined by shigeo shingo in the 1960s and implemented at toyota as part of the toyota production system (tps). Ejemplos poka yokes los medidores de equipaje en cabina de los aviones. Poka yoke es un mecanismo o proceso diseñado para evitar errores.

Inserting a pendrive in the usb slot. Noua cultură a managementului total al calității, în procesul de fabricare, ca și în sectorul serviciilor, a dat naștere unor noi modalități de îmbunătățire a calității. Este artigo objetivou avaliar a relação entre.

Safety bar at lawn mower machine shuts down to prevent that the lawn mower will drive on when. Wednesday, june 1, 2005 poka yoke slide 5 poka yoke defined shigeo shingo defines poka yoke as: Detección de obstáculos en cierre de puertas, sensores de sobrecarga, etc.

The idea was originally developed in the 1960s by shigeo shingo who was one of the ie engineers at toyota. Implement poke yoke to ensure product quality. A ser divulgado no ocidente no contexto de expansão do sistema toyota de.

Si no cabe, no lo lleves. Estos dispositivos fueron introducidos en la década de los 60 por el especialista japonés shigeo shingo, dentro metodo de producción de la multinacional toyota. This means accounting for anyone or thing that is involved in the manufacturing process.

In this order of ideas there are different types of poka yoke, depending on the situation to be improved, among them: Deste paradigma de gestão da produção. Poka yoke makes it practically impossible to have processing errors.

Mechanism which has the focal point of identification and elimination of anything that might. A ‘poka’ is an ‘inadvertent error’ and ‘yokeru’ is japanese for ‘preventing’. Shigeo shingo, an industrial engineer at toyota motor, introduced the concept of poka yoke.

In this technique the system eliminates errors or make it impossible for errors to happen. Cause a degree of variance in the manufacturing process, as.

Brasil – Aplicacao De Poka Yoke Em Processos De Caldeiraria Aplicacao De Poka Yoke Em Processos De Caldeiraria – Scielo

Lean Manufacturing Tools – Fourweekmba

Pdf Novel Poka-yoke Approaching Toward Industry-40 A Literature Review

Mengenal Metode Standar Poka Yoke – Referensi Standar

Poka-yoke At Toyota The Current State Michel Baudins Blog

Poka-yoke At Toyota The Current State Michel Baudins Blog

Poka-yoke Toyota Production System Guide – Toyota Uk Magazine

Pdf Broadening The Concept Of Poka Yoke Beyond Automotive Industry

Kaizen Lean Logistica Poka Yoke – Metodo A Prova De Falhas E Erros

Sistemas Em Obras Poka-yoke E Ferramenta De Gestao Andon

Mengenal Metode Standar Poka Yoke – Referensi Standar

Doc Pengertian Poka Yoke Dan Penerapannya Dalam Produksi D4 Near – Academiaedu

Pdf Utilizacao Do Metodo Poka-yoke Como Reducao De Custos Nos Processos Produtivos Uma Revisao De Literatura

Poka Yoke – Toyota Production System Kanban Zone

Poka Yoke – Toyota Service Concept Values – Youtube